More Than Downtime: The Overlooked Safety Benefits of Vortex Blastair Systems

MAKATI CITY, PHILIPPINES – October 18, 2025 – When plant managers discuss material blockages, the conversation almost always revolves around numbers: hours of lost production, tons of delayed output, and the high cost of maintenance. While these are critical concerns, there’s a more pressing, human-centric issue that often goes unmentioned—the significant safety risks posed by manual clean-out procedures. Staminair Corporation’s Vortex Blastair systems are engineered to address not just the economic costs, but the human ones as well.

The Silent Risk of a Clogged System

A clog in a massive silo, hopper, or kiln isn’t just a bottleneck; it’s a potential hazard. The traditional methods for clearing these blockages often require putting workers in precarious situations.

These dangers include:

Confined Space Entry: Sending personnel into silos or hoppers is one of the most high-risk activities in any industrial setting, with dangers ranging from atmospheric hazards to engulfment.

Falling Material: Manually poking and prodding at a blockage from below or above carries the immense risk of the compacted material suddenly giving way, potentially burying equipment or, worse, personnel.

Exposure to Hazards: Workers can be exposed to extreme heat near kilns and coolers or inhale hazardous dust and particulate matter during clean-outs.

Every time a manual intervention is required, the risk of an incident increases. This is where automated solutions become a crucial element of a facility’s safety culture.

Engineering a Safer Workspace

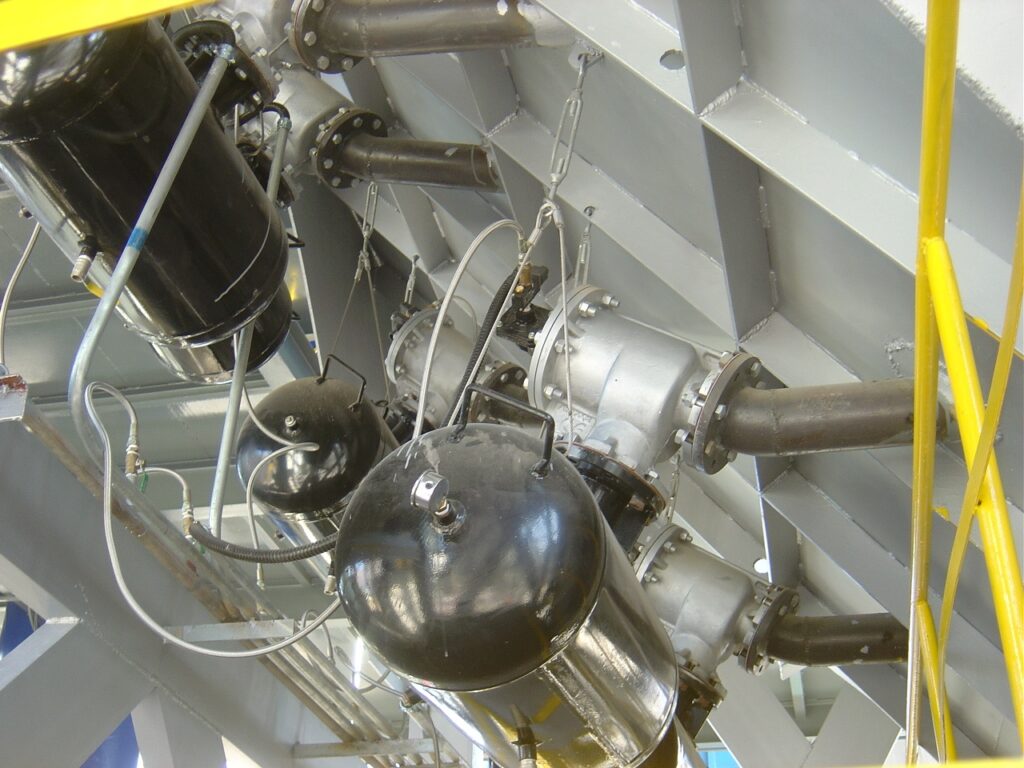

The Vortex Blastair Air Cannon is, at its core, a safety device. Its primary function is to eliminate the need for direct human intervention in a hazardous environment.

By installing a network of these powerful air cannons, operations can dislodge compacted material remotely from a safe control room. A powerful blast of compressed air does the dangerous work, ensuring that employees are kept out of harm’s way.

Furthermore, the Vortex Blastair acts as a proactive safety measure. By firing at regular intervals, the system prevents the formation of large, stubborn blockages in the first place. This drastically reduces the number of emergency situations that would ever require a high-risk manual clean-out. Even maintenance is designed with safety in mind; the simple, external T-shaped valve allows for quick service without placing technicians in awkward or dangerous positions.

“Our first priority is always the well-being of our team,” one plant manager recently commented. “Investing in a system like the Vortex Blastair isn’t just about efficiency. It’s about creating an environment where we can solve operational problems without ever compromising the safety of our people. The fact that it also boosts our productivity is the ultimate win-win.”

In the final analysis, the true cost of a material blockage isn’t just measured in lost profits, but in unacceptable risks. Staminair Corporation provides a powerful solution that protects not only your production line but, more importantly, your people. 👷♂️